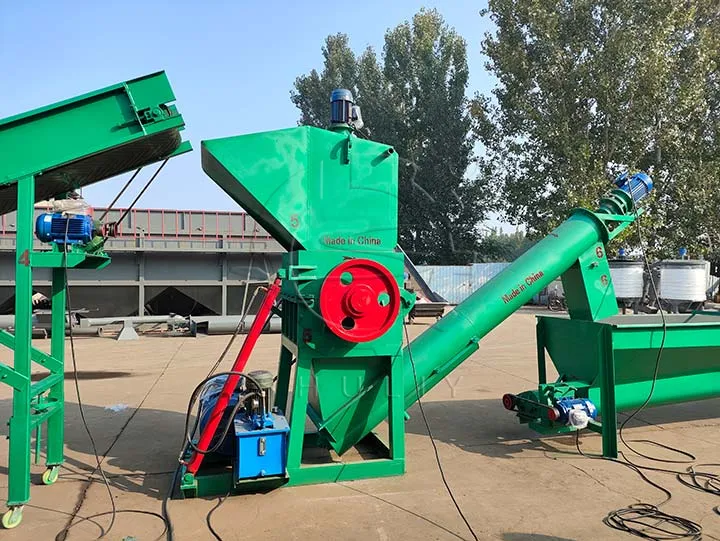

Mesin penghancur pipa HDPE merupakan peralatan penting untuk proses regenerasi sampah plastik. Beberapa komponen utama secara langsung mempengaruhi efek penghancuran dan kinerja keseluruhan penghancur botol susu plastik. Artikel ini akan fokus pada tiga komponen penting penghancur botol susu plastik: sistem layar, sistem penghancur, dan motor.

Layar penghancur pipa HDPE

Layar adalah bagian penting dari penghancur botol susu plastik. Ini bertanggung jawab untuk mengontrol ukuran partikel plastik yang dihancurkan. Ukuran dan bukaan layar yang berbeda menghasilkan pelet dengan ukuran berbeda. Layar berkualitas tinggi dapat meningkatkan efisiensi kerja penghancur botol susu plastik.

Sistem Penghancuran

Sistem penghancur botol dan penghancur kaleng meliputi pisau, dudukan pisau, batang pisau, dan sebagainya. Pisau yang bagus memastikan proses penghancuran yang merata dan efisien.

Motor Penghancur Pipa HDPE

Motor adalah sumber tenaga dari penghancur pipa HDPE dan memainkan peran kunci dalam pengoperasian penghancur botol dan kaleng secara keseluruhan. Sistem kontrol motor yang cerdas dapat memberikan operasi yang lebih fleksibel dan pemanfaatan daya yang lebih akurat, yang membantu mengurangi konsumsi energi.