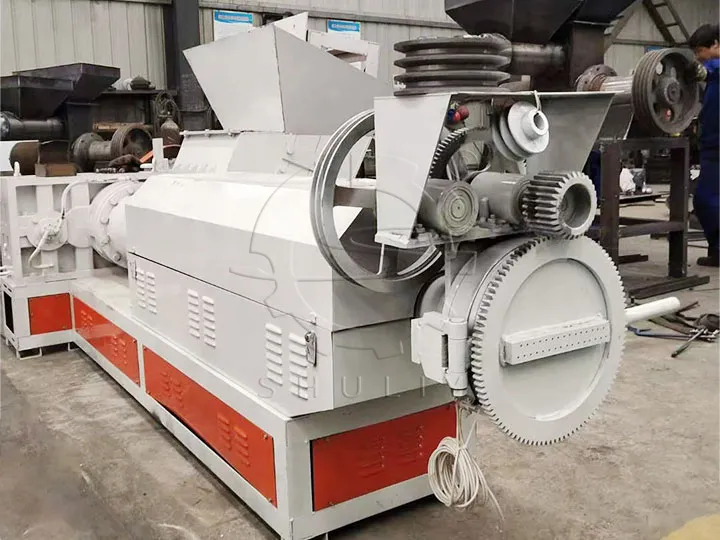

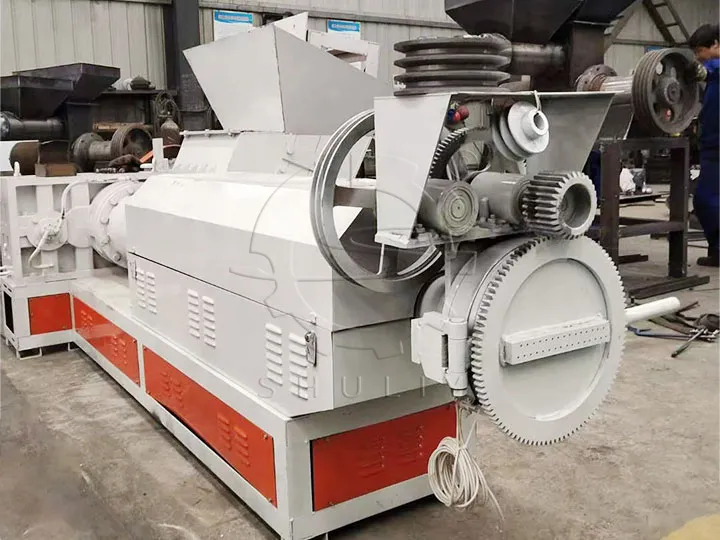

Mesin pelet busa merupakan mesin dan peralatan untuk mengolah limbah busa langsung menjadi butiran. Umumnya, granulator busa plastik perlu digunakan pada suhu yang tepat untuk mendapatkan hasil terbaik.

Penyesuaian suhu mesin pelet busa

1, tahap pra-pemanasan: Panaskan busa hingga suhu yang sesuai. Umumnya disarankan untuk memanaskan terlebih dahulu pada suhu sekitar 140℃-150℃.

2, Tahap peleburan: Masukkan busa yang sudah dipanaskan ke dalam peleburan untuk menjaga suhu yang sesuai. Umumnya disarankan untuk mengaturnya sekitar 170℃-180℃.

3, tahap pendinginan: Dinginkan busa cair menjadi butiran, dan pertahankan suhu yang sesuai. Umumnya disarankan untuk menyesuaikannya sekitar 80℃-100℃.

Operasi khusus pengaturan suhu

1、Setelah memasuki tahap peleburan, nyalakan perangkat kontrol suhu dan atur suhu sesuai dengan mesin pelet busa yang dipilih.

2、Atur kontrol suhu ekstrusi sesuai dengan situasi outlet peralatan.

3、Sesuaikan kontrol suhu perangkat cetakan sesuai dengan varietasnya.

4、Pantau apakah akan menambahkan minyak pelumas untuk mencegah plastik menempel pada granulator busa plastik.

5、Amati pengoperasian mesin pelet busa kapan saja, dan tangani situasi abnormal tepat waktu.

6、Perawatan mesin secara teratur untuk memastikan pengoperasian mesin pelet EPS yang normal.