Mesin cuci serpihan PET, juga disebut tangki wastafel pelampung plastik, memiliki dua tujuan utama. Salah satunya adalah membersihkan, menghilangkan kotoran, minyak, dan kotoran lainnya pada permukaan serpihan botol plastik sehingga serpihan botol kembali ke keadaan bersih. Yang kedua adalah perpisahan.

Dalam proses pembersihannya, pemisahan plastik sink float akan didasarkan pada perbedaan bahan tutup botol, menggunakan metode pemisahan fisik untuk memisahkan tutup botol bahan PP (polypropylene) dari serpihan botol PET.

Fitur Pemisahan Plastik Sink Float

Kemampuan Pemisahan Serbaguna

Tangki pemisah pelampung wastafel tidak hanya efektif dalam memisahkan serpihan botol PET dari tutup botol PP namun juga berperan penting dalam daur ulang PP dan PE dengan menghilangkan kotoran dari bahan secara efisien.

Kontrol Kandungan Poliolefin yang Tepat

Tangki dirancang untuk mempertahankan kontrol ketat terhadap kandungan poliolefin, memastikan kadarnya dikurangi hingga ≤200-300 mg/kg, memenuhi standar daur ulang berkualitas tinggi.

Peningkatan Kedalaman dan Tinggi

Mesin cuci serpihan PET yang ditingkatkan secara efektif mencegah serpihan botol ringan tenggelam dan terbawa saat tutup dibuka dengan meningkatkan kedalaman dan tinggi, sehingga meningkatkan efek pemisahan dan kemurnian serpihan botol.

Dilengkapi dengan Roda Dayung

Model tertentu dilengkapi dengan roda dayung, yang secara efektif mendorong material ke depan sekaligus mengaduk dan membersihkannya. Fitur ini meningkatkan efisiensi tangki dan memastikan pencucian menyeluruh.

Pentingnya Mesin Cuci Serpihan PET

Mesin pencuci botol PET memiliki peran penting dalam jalur daur ulang botol plastik, artinya pentingnya terutama tercermin pada aspek-aspek berikut:

1. Membersihkan Noda pada Serpihan Botol PET

Serpihan botol PET bekas memiliki berbagai kotoran, gemuk, debu, dan pengotor lain yang menempel pada permukaan. Pencemaran ini akan memengaruhi kualitas penggunaan kembali serpihan botol PET. Mesin pencuci serpihan PET dapat secara efisien menghilangkan polutan tersebut dan memastikan kebersihan serpihan botol melalui perendaman, pembilasan, gesekan mekanis, dan cara lain.

2. Memisahkan Serpihan Botol PET Dari Tutup PP

Karena densitas serpihan botol PET dan tutup botol PP berbeda (PET tenggelam ke dasar air dan PP melayang di permukaan), tangki pemisahan tenggelam/tenggelam dapat memanfaatkan sifat ini untuk sepenuhnya memisahkan kedua material tersebut. Ini tidak hanya meningkatkan kemurnian bahan yang didapat kembali tetapi juga berkontribusi pada kelancaran pemrosesan selanjutnya.

3. Meningkatkan Efisiensi Daur Ulang:

Serpihan botol PET yang bersih dan rapi dapat digunakan untuk memproduksi kembali produk PET baru seperti botol, serat, dan sebagainya. Melalui proses mesin pencuci serpihan PET, efisiensi penggunaan kembali botol PET bekas dapat maksimal, mengurangi kebutuhan material virgin.

Prinsip Kerja Tangki Wastafel Apung Plastik

Mesin cuci serpihan PET memisahkan tutup botol yang terbuat dari PP melalui pemisahan flotasi. Massa jenis tutup botol PP lebih kecil dari air, sedangkan massa jenis serpihan botol PET lebih besar dari air.

Pada tangki wastafel pelampung plastik, ketika pecahan botol plastik masuk ke dalam air, tutup botol PP akan mengapung di permukaan air karena massa jenisnya lebih kecil dari air, sedangkan serpihan botol PET akan tenggelam ke dasar air karena kepadatannya lebih besar dari air. Ini adalah cara pemisahan yang paling sederhana dan efektif.

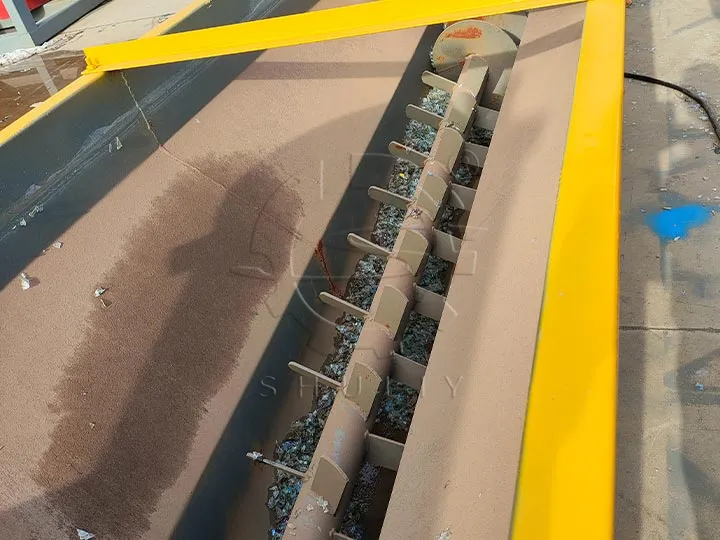

Bagian bawah tangki wastafel pelampung plastik dilengkapi dengan alat spiral yang mendorong serpihan botol PET yang tenggelam ke lantai ke proses pencucian selanjutnya.

Jumlah Pemisahan Plastik Sink Float

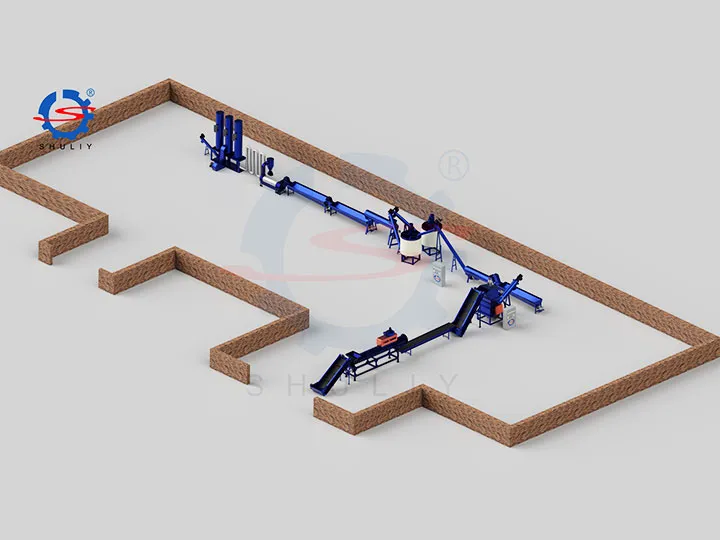

Jumlah tangki pemisah pelampung wastafel di jalur daur ulang botol PET dapat disesuaikan berdasarkan kapasitas produksi dan tingkat kontaminasi bahan.

Untuk pabrik pencucian PET dengan kapasitas 500kg/jam, dua tangki pemisahan biasanya dikonfigurasikan. Tangki pertama yang ditempatkan setelah penghancur botol PET berfungsi untuk memisahkan serpihan PET dari tutup botol. Tangki kedua, yang terletak setelah tangki cuci panas, berfungsi terutama untuk membilas. Ini membantu membersihkan lebih lanjut kontaminan dan bahan pencuci yang terbawa dari pencucian panas, memastikan nilai pH tetap dalam kisaran yang diperlukan.

Untuk jalur daur ulang dengan kapasitas 1000kg/jam, disarankan untuk mengkonfigurasi dua mesin cuci serpihan PET setelah mesin cuci panas. Pengaturan ini memastikan efisiensi pembersihan dan pemisahan yang optimal, terutama untuk pengoperasian berkapasitas tinggi.

Parameter mesin cuci serpihan PET

- Panjang: 6,0m

- Lebar: 1,2m

- Tinggi: 1,2m

- Tenaga motor: 3kw, tiga fase 380V50Hz

- Ketebalan dinding luar: 4mm

- Ketebalan pisau: 6mm