Le compacteur de mousse de polystyrène est un équipement spécialisé conçu pour traiter l'EPS (mousse de polystyrène) et est conçu pour réduire efficacement le volume du matériau en mousse. L'équipement comprime la mousse EPS en blocs serrés sous haute pression pour faciliter le stockage et le transport.

Introduction du compacteur de polystyrène

La structure d'un compacteur EPS se compose généralement d'une entrée, d'une chambre de compression et d'une sortie, ce qui le rend facile à utiliser et adapté aux opérations de recyclage de toutes tailles. Sa capacité de compression efficace réduit non seulement les coûts de transport, mais améliore également l'efficacité du recyclage, ce qui en fait un équipement important et indispensable dans l'industrie du recyclage de la mousse. En utilisant des compacteurs à froid, les entreprises peuvent gérer efficacement les déchets de mousse et réutiliser les ressources.

Il convient de mentionner que la compacteuse de polystyrène expansé (PSE) ne nécessite pas de traitement à haute température lors de la compression de la mousse, ce qui constitue la principale différence entre elle et la machine de fusion de mousse.

Avantages du compacteur EPS

- Taux de compression élevé: La mousse EPS peut être efficacement compressée en blocs ou planches denses, avec un taux de compression élevé de 40 fois, réduisant considérablement le volume.

- Aucune odeur: En adoptant la méthode de pressage à froid, aucune odeur ne sera produite pendant le processus de travail.

- Facile à entretenir: La structure du compacteur de mousse EPS est simple. La maintenance et l'entretien sont relativement faciles, ce qui peut réduire les coûts de maintenance.

- Gain de place: les blocs compressés occupent moins d’espace de stockage et sont plus faciles à gérer.

- Coûts de transport réduits: Réduisez les coûts globaux de transport en réduisant la quantité d’espace requis pendant le transport.

Comment fonctionne le compacteur de mousse EPS ?

- Tout d’abord, les déchets de mousse sont placés dans l’entrée du compacteur de recyclage de polystyrène EPS.

- Le dispositif de broyage écrase la mousse EPS en petits morceaux.

- Le compacteur de polystyrène est activé. Un dispositif mécanique ou un système hydraulique commence à appliquer une pression uniforme et continue sur la mousse.

- Sous pression continue, le matériau en mousse est progressivement comprimé en blocs ou dalles plus denses.

- Les blocs ou panneaux de mousse comprimés peuvent être retirés de l'orifice de décharge du compacteur de mousse pour un stockage, un transport ou un retraitement ultérieur.

Vidéo de travail de la machine de compactage EPS

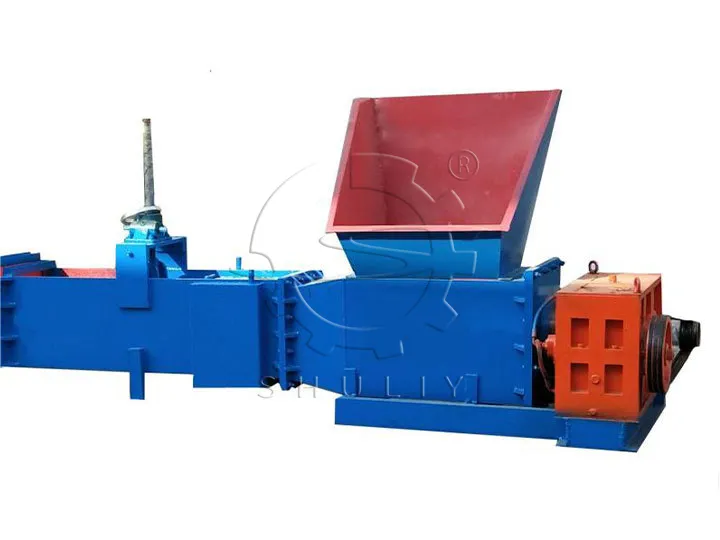

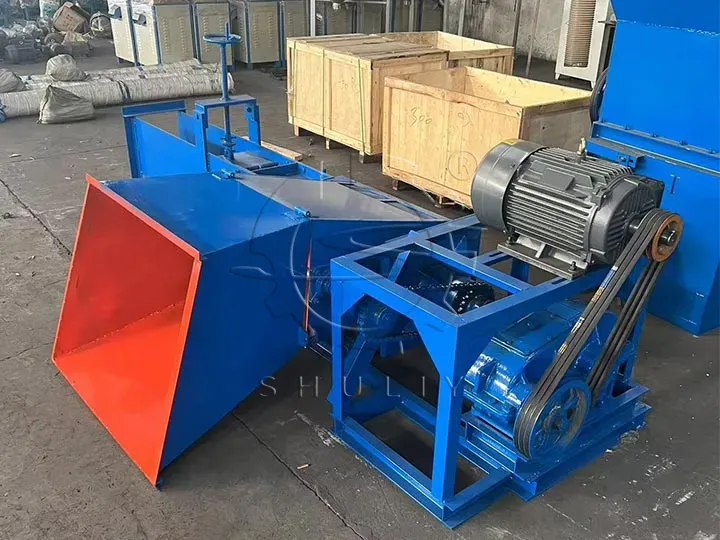

2 types de machines de densification

Nous proposons deux types de machines densificateurs, verticales et horizontales. Le compacteur vertical en polystyrène EPS adopte la méthode d'alimentation par le haut, facile à utiliser et adaptée aux occasions avec un petit espace ; tandis que le compacteur de mousse horizontal adopte une méthode d'alimentation latérale, avec l'entrée au ras du sol, ce qui est pratique pour un placement rapide du matériau. Ces deux conceptions ont leurs avantages et vous pouvez choisir le bon équipement en fonction de vos besoins spécifiques.

Compacteuse verticale de polystyrène expansé PSE

Paramètres du compacteur de polystyrène

| Modèle | 260 | 300 | 350 | 400 |

| Puissance (kW) | 7.5 | 11 | 11 | 15 |

| Ratio de compression | 40:01:00 | 40:01:00 | 40:01:00 | 40:01:00 |

| Taille d'entrée (mm) | 600*800*1400 | 600*800*1400 | 800*900*1400 | 800*900*1600 |

| Taille de sortie (mm) | 260*260 | 280*280 | 350*350 | 400*400 |

| Capacité | 400-600 | 400-600 | 600-800 | 800-1000 |

| Poids | 600 | 700 | 800 | 1200 |

Cas réussi

L'un de nos clients de Malaisie a été confronté au problème de l'élimination d'une grande quantité de déchets de mousse. Ces déchets de mousse prenaient beaucoup de place lors du transport et du stockage, ce qui entraînait de grandes difficultés de recyclage. Après consultation et analyse par l’équipe professionnelle de Shuliy, nous avons recommandé notre compacteur de polystyrène à nos clients pour résoudre ce problème.

Le client a considérablement réduit le volume de mousse après avoir utilisé le compacteur de mousse EPS. Cela leur a permis de stocker et de transporter les déchets plus efficacement, économisant ainsi des ressources et des coûts importants.

Pour plus de détails : Compacteuse de polystyrène PSE envoyée en Malaisie