Der Styroporverdichter ist ein Spezialgerät zur Verarbeitung von EPS (Polystyrolschaum) und soll das Volumen des Schaummaterials effektiv reduzieren. Die Anlage komprimiert EPS-Schaum durch hohen Druck zu dichten Blöcken, um Lagerung und Transport zu erleichtern.

Einführung des Styroporverdichters

Die Struktur eines EPS-Verdichters besteht normalerweise aus einem Einlass, einer Kompressionskammer und einem Auslass, wodurch er einfach zu bedienen und für Recyclingbetriebe jeder Größe geeignet ist. Seine effiziente Komprimierungskapazität senkt nicht nur die Transportkosten, sondern verbessert auch die Recyclingeffizienz und macht ihn zu einem wichtigen und unverzichtbaren Gerät in der Schaumstoffrecyclingindustrie. Durch den Einsatz von Kaltverdichtermaschinen können Unternehmen Schaumabfälle effektiv verwalten und Ressourcen wiederverwenden.

Erwähnenswert ist, dass der EPS-Styropor-Verdichter keine Hochtemperaturbehandlung beim Verdichten des Schaums erfordert, was der Hauptunterschied zu einer Schaumstoff-Schmelzmaschine ist.

Vorteile des EPS-Verdichters

- Hohes Kompressionsverhältnis: EPS-Schaum kann mit einem hohen Kompressionsverhältnis von 40-fach effektiv zu dichten Blöcken oder Brettern komprimiert werden, wodurch das Volumen erheblich reduziert wird.

- Kein Geruch: Durch die Kaltpressmethode entsteht während des Arbeitsprozesses kein Geruch.

- Leicht zu pflegen: Die Struktur des EPS-Schaumverdichters ist einfach. Wartung und Instandhaltung sind relativ einfach, wodurch die Wartungskosten gesenkt werden können.

- Platzsparend: Komprimierte Blöcke beanspruchen weniger Speicherplatz und sind einfacher zu verwalten.

- Reduzierte Transportkosten: Reduzieren Sie die Gesamttransportkosten, indem Sie den Platzbedarf während des Transports reduzieren.

Wie funktioniert der EPS-Schaumverdichter?

- Zunächst wird das Altschaummaterial in den Einlass des EPS-Styropor-Recycling-Verdichters gegeben.

- Das Zerkleinerungsgerät zerkleinert den EPS-Schaum in kleine Stücke.

- Der Styroporverdichter wird aktiviert. Ein mechanisches Gerät oder Hydrauliksystem beginnt, einen gleichmäßigen und kontinuierlichen Druck auf den Schaum auszuüben.

- Unter kontinuierlichem Druck wird das Schaumstoffmaterial nach und nach zu dichteren Blöcken oder Platten verdichtet.

- Die komprimierten Schaumstoffblöcke oder -platten können zur anschließenden Lagerung, zum Transport oder zur Wiederaufbereitung aus der Auslassöffnung der Schaumverdichtermaschine entnommen werden.

Arbeitsvideo der EPS-Verdichtungsmaschine

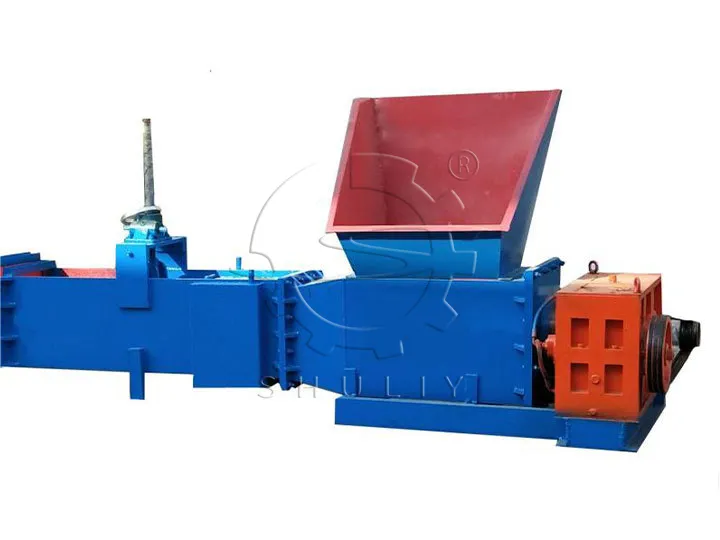

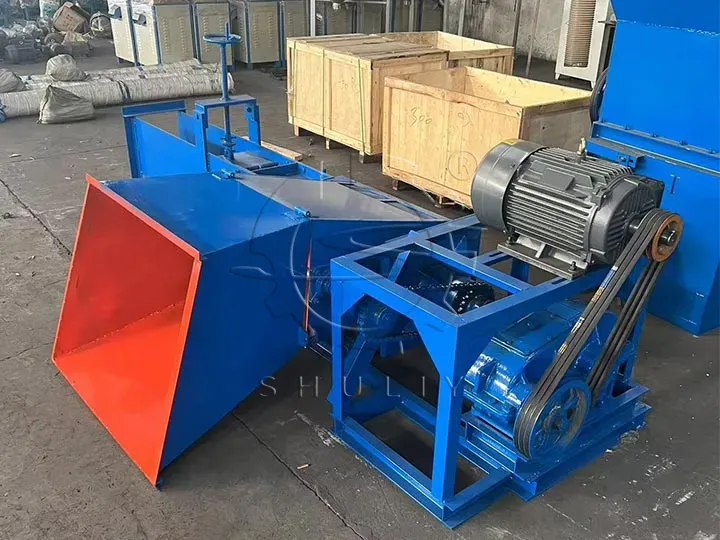

2 Arten von Verdichtungsmaschinen

Wir bieten zwei Arten von Verdichtermaschinen an: vertikale und horizontale. Der vertikale EPS-Styroporverdichter verwendet die Top-Zuführmethode, die einfach zu bedienen und für Anlässe mit wenig Platz geeignet ist. während der horizontale Schaumverdichter die seitliche Zufuhrmethode anwendet, wobei der Einlass bündig mit dem Boden abschließt, was für eine schnelle Materialplatzierung praktisch ist. Diese beiden Ausführungen haben ihre Vorteile und Sie können die richtige Ausrüstung entsprechend Ihren spezifischen Bedürfnissen auswählen.

Vertikaler EPS-Styropor-Verdichter

Parameter des Styroporverdichters

| Modell | 260 | 300 | 350 | 400 |

| Leistung (kW) | 7.5 | 11 | 11 | 15 |

| Kompressionsrate | 40:01:00 | 40:01:00 | 40:01:00 | 40:01:00 |

| Eingabegröße (mm) | 600*800*1400 | 600*800*1400 | 800*900*1400 | 800*900*1600 |

| Ausgabegröße (mm) | 260*260 | 280*280 | 350*350 | 400*400 |

| Kapazität | 400-600 | 400-600 | 600-800 | 800-1000 |

| Gewicht | 600 | 700 | 800 | 1200 |

Erfolgreicher Fall

Einer unserer Kunden aus Malaysia stand vor dem Problem, eine große Menge Schaumabfall zu entsorgen. Diese Schaumabfälle nahmen beim Transport und bei der Lagerung viel Platz ein, was zu großen Schwierigkeiten beim Recycling führte. Nach Beratung und Analyse durch das professionelle Team von Shuliy haben wir unseren Kunden unseren Styroporverdichter zur Lösung dieses Problems empfohlen.

Der Kunde hat das Schaumvolumen nach dem Einsatz des EPS-Schaumverdichters deutlich reduziert. Dadurch konnten sie den Abfall effizienter lagern und transportieren und so erhebliche Ressourcen und Kosten einsparen.

Weitere Details: EPS-Styropor-Verdichter nach Malaysia gesendet