Máy nén xốp là một thiết bị chuyên dụng được thiết kế để xử lý EPS (Polystyrene Foam) và được thiết kế để giảm thể tích của vật liệu xốp một cách hiệu quả. Thiết bị nén xốp EPS thành khối chặt chẽ nhờ áp suất cao giúp dễ dàng bảo quản và vận chuyển.

Giới thiệu máy ép xốp

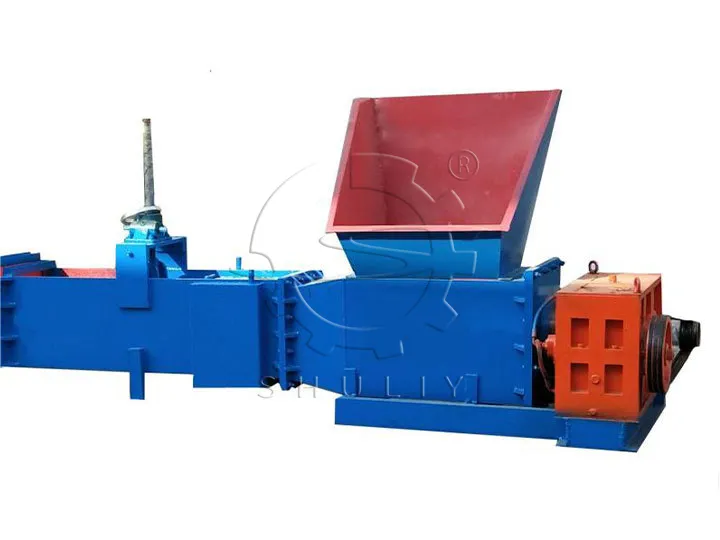

Cấu tạo của máy đầm EPS thường bao gồm cửa vào, buồng nén và cửa ra, giúp vận hành dễ dàng và phù hợp với các hoạt động tái chế ở mọi quy mô. Khả năng nén hiệu quả của nó không chỉ làm giảm chi phí vận chuyển mà còn cải thiện hiệu quả tái chế, khiến nó trở thành một thiết bị quan trọng và không thể thiếu trong ngành tái chế bọt. Bằng cách sử dụng máy đầm nén lạnh, các công ty có thể quản lý hiệu quả chất thải bọt và tái sử dụng tài nguyên.

Cần lưu ý rằng máy ép xốp EPS không yêu cầu xử lý nhiệt độ cao khi nén bọt, đây là điểm khác biệt chính giữa nó và máy nấu chảy bọt.

Ưu điểm của máy đầm EPS

- Tỷ lệ nén cao: Bọt xốp EPS có thể được nén hiệu quả thành các khối hoặc tấm dày đặc, với tỷ lệ nén cao 40 lần, giúp giảm thể tích đáng kể.

- Không có mùi: Áp dụng phương pháp ép nguội, trong quá trình làm việc sẽ không tạo ra mùi hôi.

- Dễ dàng bảo trì: Cấu trúc máy nén xốp EPS rất đơn giản. Bảo trì và bảo trì tương đối dễ dàng, có thể giảm chi phí bảo trì.

- Tiết kiệm không gian: các khối nén chiếm ít không gian lưu trữ hơn và dễ quản lý hơn.

- Giảm chi phí vận chuyển: Giảm chi phí vận chuyển tổng thể bằng cách giảm lượng không gian cần thiết trong quá trình vận chuyển.

Máy nén bọt EPS hoạt động như thế nào?

- Đầu tiên, vật liệu xốp thải được đưa vào đầu vào của máy nén tái chế xốp EPS.

- Thiết bị nghiền nghiền xốp EPS thành từng miếng nhỏ.

- Máy nén xốp được kích hoạt. Một thiết bị cơ khí hoặc hệ thống thủy lực bắt đầu tạo áp suất đồng đều và liên tục lên bọt.

- Dưới áp suất liên tục, vật liệu xốp được nén dần thành các khối hoặc tấm dày đặc hơn.

- Các khối hoặc tấm xốp đã nén có thể được tháo ra khỏi cổng xả của máy đầm bọt để lưu trữ, vận chuyển hoặc tái xử lý tiếp theo.

Video hoạt động của máy đầm EPS

2 loại máy cô đặc

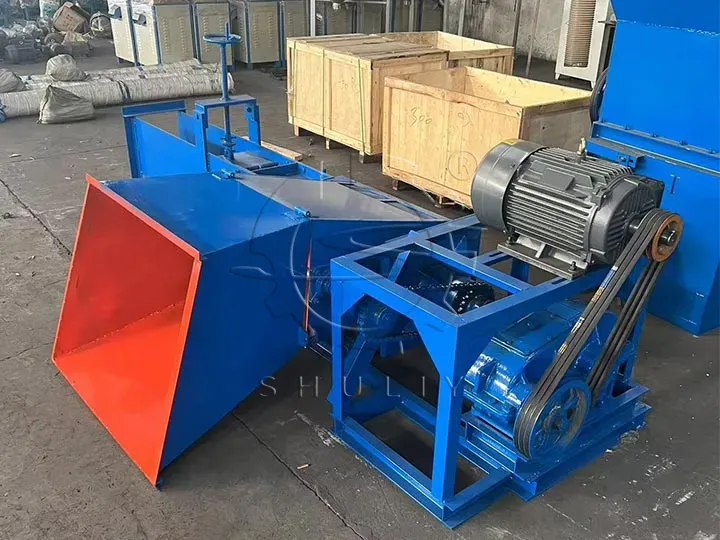

Chúng tôi cung cấp hai loại máy làm đặc, dọc và ngang. Máy nén xốp EPS dọc áp dụng phương pháp cấp liệu hàng đầu, dễ vận hành và phù hợp trong những trường hợp có không gian nhỏ; trong khi máy đầm bọt ngang áp dụng phương pháp cấp liệu bên, với đầu vào ngang bằng với mặt đất, thuận tiện cho việc đổ vật liệu nhanh chóng. Hai thiết kế này đều có những ưu điểm riêng và bạn có thể chọn thiết bị phù hợp theo nhu cầu cụ thể của mình.

Máy ép xốp EPS dạng đứng

Thông số của máy ép xốp

| Người mẫu | 260 | 300 | 350 | 400 |

| Công suất (kW) | 7.5 | 11 | 11 | 15 |

| Tỷ lệ nén | 40:01:00 | 40:01:00 | 40:01:00 | 40:01:00 |

| Kích thước đầu vào (mm) | 600*800*1400 | 600*800*1400 | 800*900*1400 | 800*900*1600 |

| Kích thước đầu ra (mm) | 260*260 | 280*280 | 350*350 | 400*400 |

| Dung tích | 400-600 | 400-600 | 600-800 | 800-1000 |

| Cân nặng | 600 | 700 | 800 | 1200 |

Trường hợp thành công

Một trong những khách hàng của chúng tôi đến từ Malaysia đã phải đối mặt với vấn đề xử lý một lượng lớn chất thải xốp. Những chất thải xốp này chiếm nhiều không gian trong quá trình vận chuyển và lưu trữ, gây khó khăn lớn cho việc tái chế. Sau khi được đội ngũ chuyên nghiệp của Shuliy tư vấn và phân tích, chúng tôi đã giới thiệu máy nén xốp cho khách hàng để giải quyết vấn đề này.

Khách hàng đã giảm đáng kể khối lượng bọt sau khi sử dụng máy nén bọt EPS. Điều này cho phép họ lưu trữ và vận chuyển chất thải hiệu quả hơn, tiết kiệm đáng kể nguồn lực và chi phí.

Để biết thêm chi tiết: Máy ép xốp EPS được gửi đến Malaysia