O compactador de isopor é um equipamento especializado projetado para processar EPS (espuma de poliestireno) e tem como objetivo reduzir efetivamente o volume do material de espuma. O equipamento comprime a espuma EPS em blocos compactos por meio de alta pressão para fácil armazenamento e transporte.

Introdução do compactador de isopor

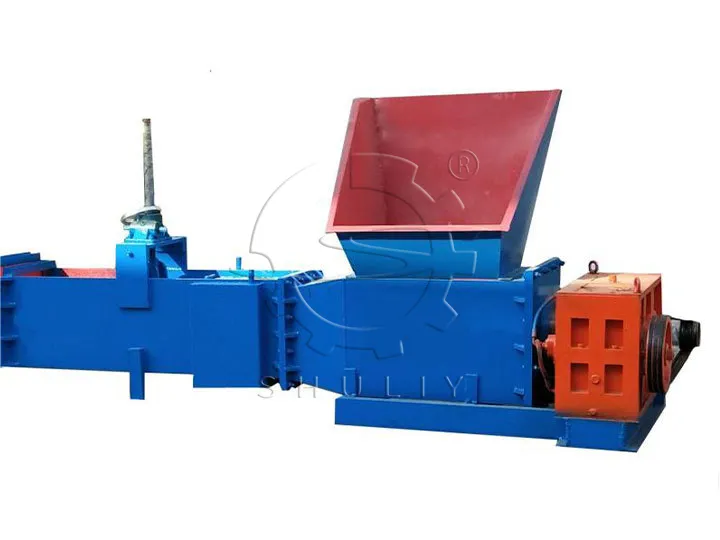

A estrutura de um compactador EPS geralmente consiste em entrada, câmara de compressão e saída, o que o torna fácil de operar e adequado para operações de reciclagem de todos os tamanhos. A sua eficiente capacidade de compressão não só reduz os custos de transporte, mas também melhora a eficiência da reciclagem, tornando-o um equipamento importante e indispensável na indústria de reciclagem de espuma. Ao usar máquinas compactadoras a frio, as empresas podem gerenciar com eficácia os resíduos de espuma e reutilizar recursos.

Vale a pena mencionar que o compactador de EPS não requer tratamento a altas temperaturas ao comprimir a espuma, que é a principal diferença entre ele e a máquina de derretimento de espuma.

Vantagens do compactador EPS

- Alta taxa de compressão: A espuma EPS pode ser efetivamente comprimida em blocos ou placas densas, com uma alta taxa de compressão de 40 vezes, reduzindo bastante o volume.

- Sem odor: Adotando o método de prensagem a frio, nenhum odor será produzido durante o processo de trabalho.

- Fácil de manter: A estrutura do compactador de espuma EPS é simples. A manutenção e conservação são relativamente fáceis, o que pode reduzir o custo de manutenção.

- Economia de espaço: os blocos compactados ocupam menos espaço de armazenamento e são mais fáceis de gerenciar.

- Custos de transporte reduzidos: Reduza os custos gerais de transporte, reduzindo a quantidade de espaço necessária durante o transporte.

Como funciona o compactador de espuma EPS?

- Primeiro, o material residual de espuma é colocado na entrada do compactador de reciclagem de isopor EPS.

- O dispositivo de trituração esmaga a espuma EPS em pequenos pedaços.

- O compactador de isopor é acionado. Um dispositivo mecânico ou sistema hidráulico passa a aplicar uma pressão uniforme e contínua à espuma.

- Sob pressão contínua, o material de espuma é gradualmente comprimido em blocos ou placas mais densos.

- Os blocos ou placas de espuma comprimida podem ser removidos da porta de descarga da máquina compactadora de espuma para posterior armazenamento, transporte ou reprocessamento.

Vídeo de trabalho da máquina compactadora EPS

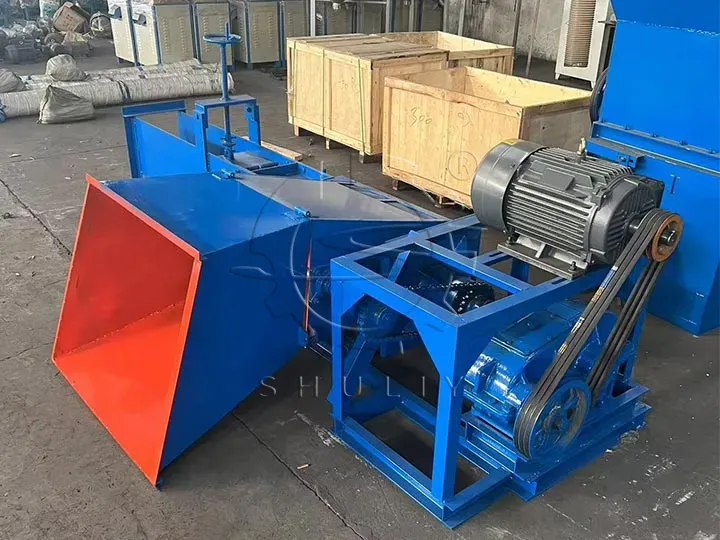

2 tipos de máquinas densificadoras

Oferecemos dois tipos de máquinas densificadoras, verticais e horizontais. O compactador vertical de isopor EPS adota o método de alimentação superior, que é fácil de operar e adequado para ocasiões com espaço pequeno; enquanto o compactador de espuma horizontal adota o método de alimentação lateral, com a entrada nivelada com o solo, o que é conveniente para a rápida colocação do material. Esses dois designs têm suas vantagens e você pode escolher o equipamento certo de acordo com suas necessidades específicas.

Compactador de espuma de poliestireno EPS vertical

Parâmetros do compactador de isopor

| Modelo | 260 | 300 | 350 | 400 |

| Potência (kW) | 7.5 | 11 | 11 | 15 |

| Taxa de compressão | 40:01:00 | 40:01:00 | 40:01:00 | 40:01:00 |

| Tamanho de entrada (mm) | 600*800*1400 | 600*800*1400 | 800*900*1400 | 800*900*1600 |

| Tamanho de saída (mm) | 260*260 | 280*280 | 350*350 | 400*400 |

| Capacidade | 400-600 | 400-600 | 600-800 | 800-1000 |

| Peso | 600 | 700 | 800 | 1200 |

Caso de sucesso

Um de nossos clientes da Malásia enfrentou o problema de descartar uma grande quantidade de resíduos de espuma. Esses resíduos de espuma ocupavam muito espaço durante o transporte e armazenamento, o que causava grandes dificuldades na reciclagem. Após consulta e análise da equipe de profissionais da Shuliy, recomendamos nosso compactador de isopor aos nossos clientes para solucionar este problema.

O cliente reduziu significativamente o volume de espuma após utilizar o compactador de espuma EPS. Isto permitiu-lhes armazenar e transportar os resíduos de forma mais eficiente, poupando recursos e custos significativos.

Para mais detalhes: Compactador de Espuma de EPS Enviado para a Malásia