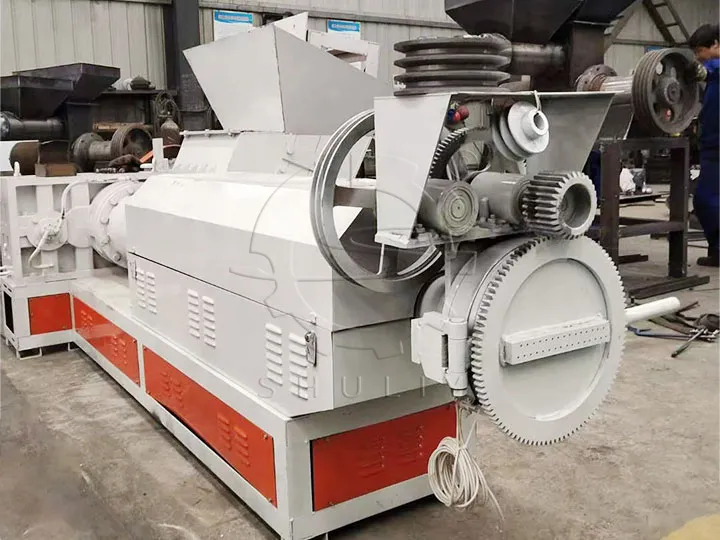

Untuk memastikan granulator busa berfungsi dengan baik dan menghasilkan jenis pelet daur ulang yang tepat, ada beberapa hal yang perlu diperhatikan. Di bawah ini adalah langkah-langkah penting dalam prosedur pengoperasian granulator EPS.

Kontrol suhu dan kadar air

Bahan dalam granulator busa harus dipertahankan pada suhu optimum dalam kisaran 50 hingga 80°C. Kadar kelembaban sebaiknya dipertahankan antara 2,5% dan 7,5% untuk memastikan kondisi granulasi yang sesuai.

Selama pengoperasian normal pelet busa plastik, suhu mesin harus tetap stabil, menghindari suhu tinggi dan rendah yang tiba-tiba. Bagian kepala dekat lubang ventilasi harus dijaga pada suhu sekitar 200°C.

Persiapan granulator busa sebelum memulai

Sebelum memulai granulator busa, lakukan terlebih dahulu sekitar 30 menit untuk memanaskan suhu ke tingkat yang diperlukan. Selanjutnya, sabuk delta motor ditarik secara manual untuk memastikan putaran kerja normal. Kemudian pemanasan dilanjutkan hingga memenuhi suhu granulasi plastik yang sifatnya berbeda.

Pembersihan granulator busa plastik

Saat granulator EPS berhenti, pastikan untuk memutus aliran listrik sepenuhnya untuk memastikan keamanan. Steker sekrup kepala pelet busa plastik (dengan bagian kunci pas) harus dilepas pada saat dimatikan, tunggu waktu berikutnya sebelum digunakan untuk pemanasan secara terpisah.