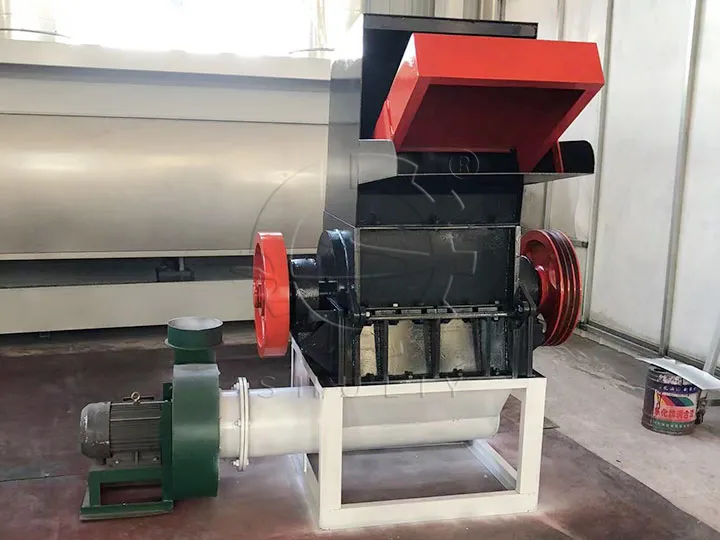

Mesin penghancur plastik otomatis dapat dibagi menjadi beberapa jenis sesuai dengan struktur, prinsip kerja, dan skenario penerapannya. Mesin penghancur plastik kecil yang berbeda memiliki karakteristik dan cakupan aplikasinya masing-masing dan dapat dipilih sesuai dengan kebutuhan sebenarnya. Munculnya mesin penghancur plastik otomatis memberikan kemudahan yang luar biasa untuk mendaur ulang plastik. Blog ini akan memperkenalkan penghancur plastik secara detail.

Prinsip kerja mesin penghancur plastik otomatis

Prinsip kerja daur ulang penggiling plastik terutama untuk menghancurkan sampah plastik menjadi partikel-partikel kecil melalui efek tumbukan dan geser antara pemotong berputar berkecepatan tinggi dan pemotong tetap. Pada saat yang sama, selama proses penghancuran, partikel plastik juga akan digiling dan dimurnikan sampai batas tertentu, untuk lebih meningkatkan efisiensi daur ulang.

Mesin penghancur kecil untuk aplikasi plastik

Penghancur kecil untuk plastik banyak digunakan dalam industri daur ulang plastik. Ini dapat digunakan untuk menghancurkan berbagai jenis limbah plastik, seperti botol plastik, kantong plastik, tabung plastik, dan sebagainya. Pada saat yang sama, mesin penghancur plastik otomatis juga dapat mengklasifikasikan dan menyempurnakan berbagai jenis limbah plastik untuk digunakan kembali dan pemrosesan sumber daya selanjutnya.

Keunggulan mesin penghancur plastik otomatis

- Meningkatkan efisiensi daur ulang: Dengan menghancurkan sampah plastik menjadi partikel-partikel kecil, efisiensi daur ulang plastik dapat ditingkatkan secara signifikan dan sampah dapat dikurangi.

- Mengurangi biaya: penggunaan mesin penghancur plastik otomatis dapat mengurangi biaya daur ulang dan penggunaan kembali, serta meningkatkan efisiensi ekonomi.

- Mengurangi polusi plastik: penghancuran dan pemurnian sampah plastik dapat mengurangi dampak terhadap lingkungan dan polusi.

- Beragam aplikasi: Daur ulang penggiling plastik dapat diterapkan pada berbagai jenis sampah plastik, dengan beragam aplikasi.